Blog

Trải nghiệm công nghệ truy xuất quy trình minh bạch

1. Introduction

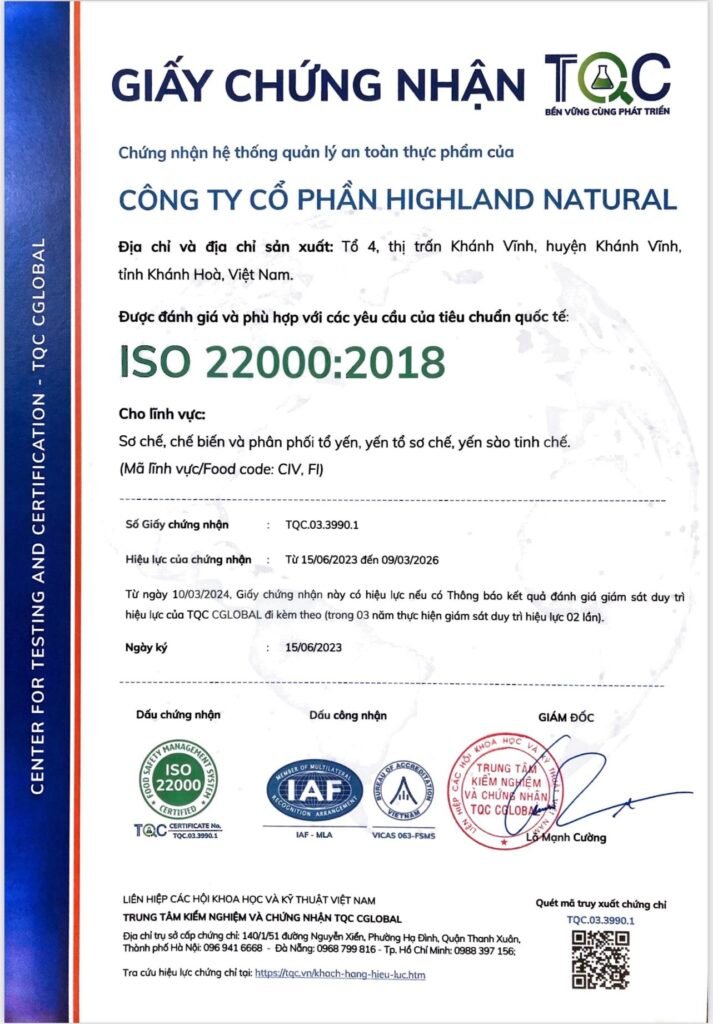

Pacific Bird Nest is proud to own a completely closed bird’s nest production line, ISO 22000:2018 certification for food safety management, quality assurance and safety for consumers’ health.

Pacific Bird’s Nest is constantly striving to improve the management process and improve product quality, with the desire to create a quality product, cohesive with community responsibility.

2. Pacific and transparent process traceability technology:

Due to the increasing demand for bird’s nests, the production and trading of bird’s nests has become a large industry, but at the same time, there are also many problems such as product counterfeiting, low-quality bird’s nests, the use of tricks and chemicals to compete on prices, affecting product quality and consumer health.

Understanding the psychology of customers, Pacific Bird Nest has applied transparent process traceability technology to its bird’s nest production. Thereby helping customers:

- Know the exact origin of the product.

- Control 100% pure product quality as committed through live video.

- Peace of mind with the scientific production process of preserving bird’s nest micronutrients.

All towards consumer trust.

3. Parts in the production process

Staff is picking up the bird’s nest feather carefully and meticulously.

The room for production, nest drying and storage at 24/24 standard temperature preserves the best bird’s nest micronutrients.

4. Pacific Bird nest – committed to quality product for costumer’s health

- Committed to 100% pure, no oil, no salt, no sugar, no filters, no bleaching chemicals.

- Obtained US FDA certification.

- The production process is closed and meets international standards ISO 22000:2018.

- Quality products, luxurious packaging – Perfect choice for gifts for partners and customers.

- 300% refund if the bird’s nest is fake. Guaranteed 100% pure natural bird’s nest.